Automatically identifies skipped or non-standard steps, reducing risks and rework.

Ensures execution strictly follows the sequence defined by Engineering standards.

Records visual evidence and critical operational events,supporting audits, investigations, and continuous improvement.

Acts preventively by identifying deviations before they become defects or quality losses.

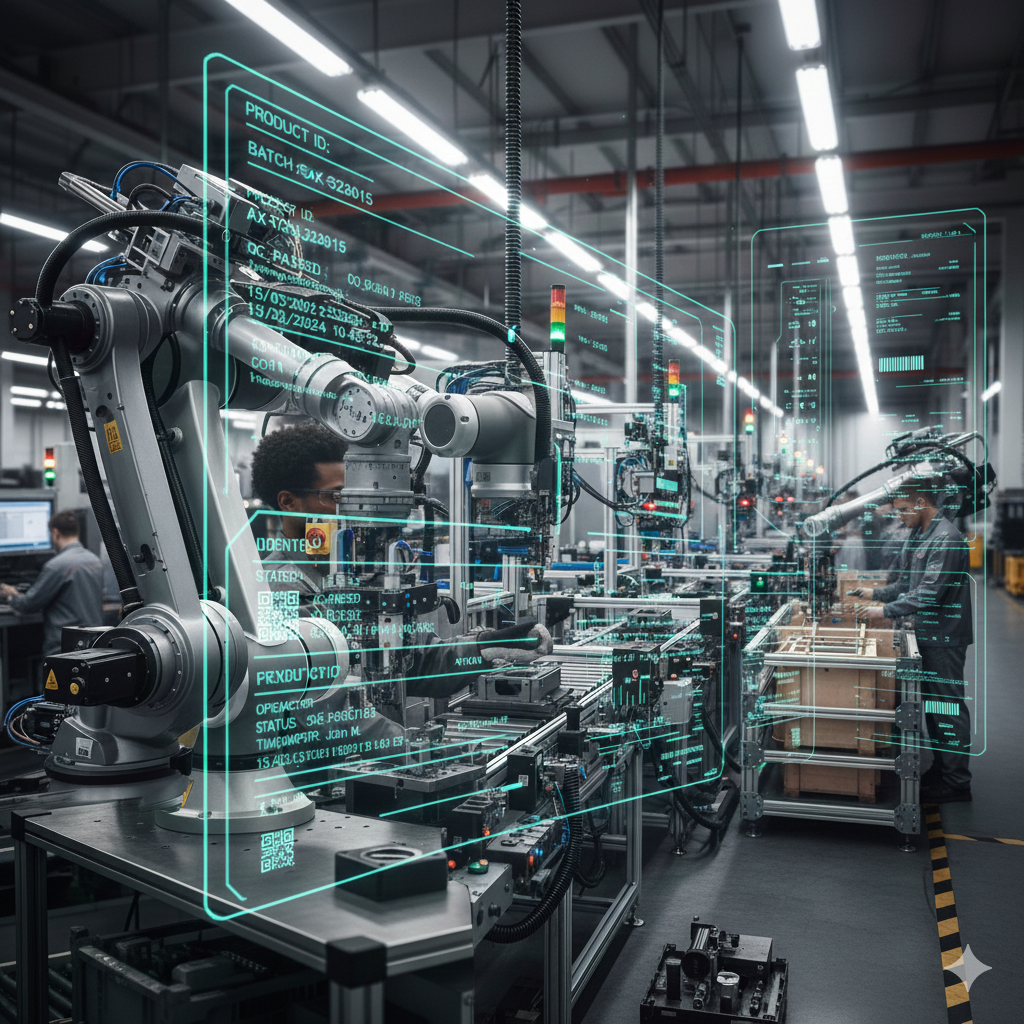

Real comparison between standard-compliant execution and deviation scenarios, demonstrating OPERA GUARD’s action directly at the source of failure.

OPERA GUARD was born from real industrial experience, created by those who lived the challenges of execution on the shop floor — not in a laboratory.

Company responsible for OPERA GUARD development

Company responsible for OPERA GUARD development

OPERA GUARD was created by Marcelo Gonçalves, an engineer with over 15 years of experience in continuous improvement, quality, supply chain, and production.

This is not a generic AI solution. It is engineering applied to operational execution.